Coffee Roasting Mills: Criteria for a Safe Choice

Choosing the ideal mill directly impacts coffee quality, productivity, and process safety. On an industrial scale, the decision also influences maintenance costs, energy consumption, and overall plant performance. Therefore, it is important to evaluate the equipment's capacity, furniture standardization, level of automation, protection against foreign objects, and the acoustic comfort of the team.

Types of Mills

Knowing the models helps to choose accurately. The main ones are:

- Burr/Disc: offer uniform particle size and low thermal variation, suitable for more demanding standards.

- Blade: simple and productive; generate irregular particles and more heat, but in industrial versions with controls and separators deliver high performance.

- Hammer and Industrial: geared towards coarse grinding and high capacity, common in blends and pre-processing.

In the industry, the preference is usually for robust burrs or equipment with automatic protection and cleaning. Still, automated blade mills can be excellent for operations that prioritize productivity and practical maintenance.

Understanding your roasting profile

Before defining the equipment, it is essential to analyze the operation profile. Daily volume, type of coffee (traditional, superior, gourmet or specialty), sales formats and growth projections help determine the ideal grinding capacity. Thus, the flow between roasting, resting and packaging remains balanced.

It is also important to consider how many production cycles the plant performs and the level of automation already existing in the silos, roasting and packaging. In modern lines, the mill should integrate into the system and facilitate monitoring and control.

Production capacity and power

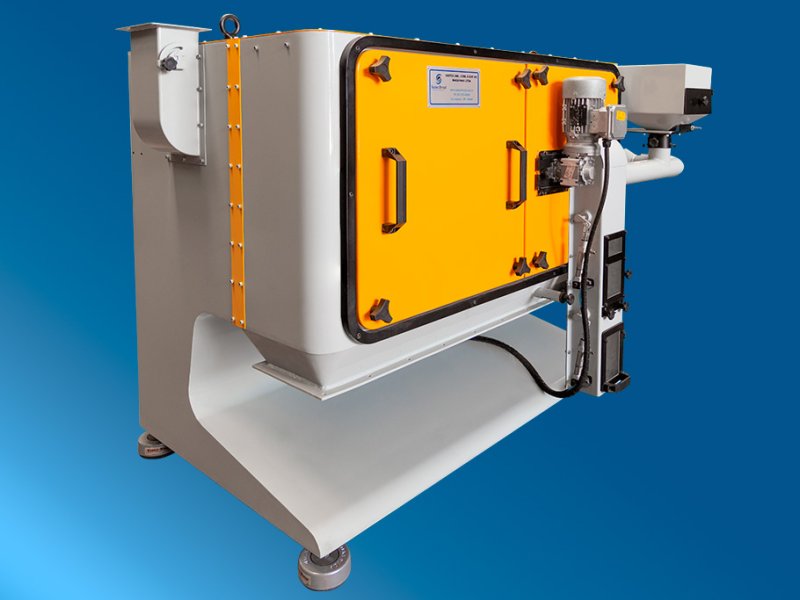

The mill needs to keep up with the pace of the roasters without creating bottlenecks. The SIATEC Brasil® automated blade grinding system offers 15, 25 and 40 hp motors, with capacities that can reach more than 1,600 kg/h, depending on the equipment configuration and product conditions.

Grinding Quality and Safety

The particle size must be stable, repeatable, and aligned with the brand's standard. Furthermore, process safety is essential. Magnetic plates and automatic separators prevent ferrous fragments or stones from advancing into the grinding process, avoiding damage and preserving product integrity.

In the industrial segment, choosing a mill that already incorporates protection systems reduces risks, increases reliability, and ensures a cleaner and safer production flow.

Automation and Operational Stability

Automation has gained ground in roasting plants because it improves performance and predictability. Electrical panels with frequency inverters and ramp control make starts smoother, protect the motor, and stabilize operation.

Solutions that already include these features from the factory usually offer better daily performance and facilitate the work of operators, who then work in a more controlled environment.

Acoustic Comfort and Working Conditions

Noise directly impacts the well-being of the team. Therefore, it is important to prioritize equipment with acoustic insulation.

SIATEC Brasil® uses insulation and vibration dampers in the blade mill, reducing noise and vibrations and improving operating conditions.

Cleaning, maintenance and reliability

The efficiency of the mill depends on regular cleaning. Accumulated residues can alter the particle size and increase the risk of overheating. Therefore, it is important to choose models with easy access and automatic screen cleaning systems, which maintain a stable flow and reduce downtime.

High-efficiency motors also contribute to longer service life and energy performance over time.

Why consider the SIATEC Brasil® solution?

With over two decades of experience in roasting technology, SIATEC develops complete and integrated industrial equipment. Automated blade grinding combines productivity, protection, acoustic insulation, automation and high-efficiency motors in a single unit, ensuring batch stability.

Next steps

After reviewing capacity, safety, automation, noise and maintenance, the ideal is to align these criteria with your plant design. Talking to a specialized technical team helps to size the correct solution.

On the SIATEC Brasil® website, you can find specifications for the automated blade grinding system and request a detailed quote, facilitating a safe choice aligned with the quality and productivity goals of your roasting operation.